Automatic control of injection system for overhead

Products list- High Precision Electrical Resistance Probe Corrosion Monitoring System

- LPR Probe corrosion monitoring system

- Two inch access fitting assembly

- Coupon corrosion monitoring system

- Integrated online corrosion monitoring system

- Retrievers & Service valves

- Corrosion and protection management system

- Automatic cleaning and maintaining system for pH electrode

- Automatic control of injection system for overhead

- Online High Temperature Ultrasonic Thickness Measurement system

- Online Electric Field Matrix Thickness Measurement system

- Portable corrosion monitoring instruments

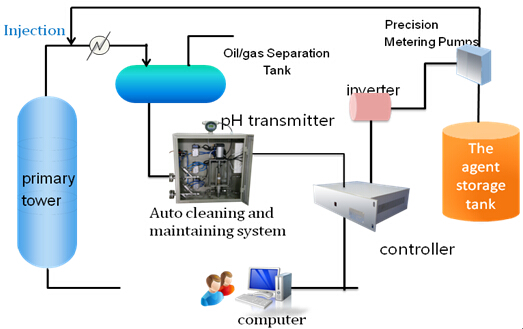

The overhead pH value control is an important procedure in the process of oil refining. The automatic control system of oil refining equipment overhead ammonia injection and pH value is a system under which a proper control model for the production process of oil refining equipment is established, distillation tower overhead ammonia injection can be automatically adjusted, the pH value of overhead gas line can be controlled within the expected range, and the equipment corrosion state can be real-time monitored by inductance probe corrosion monitoring technique, so as to improve the mathematical model which controls the overhead ammonia injection, make the production process more stable and realize effective corrosion control.

Technical Features

·High control precision

·Strong adaptability, good robustness

·Small overshoot

System diagram

Typical items

Injection automatic controller

Model:

·ZK5800(1:1 point to point)

·ZK5810(1:2 point to point)

·ZK5820(1:3 point to point)

Technical parameters:

·Resolution: 12-bit A/D converter

·Control accuracy:≤0.3pH

·Ambient temperature:0℃~50℃

·Relative humidity:≤85%

·Working voltage:220VAC

Frequency converter

Model: ZK5400 /ZK5410

Technical parameters

·Frequency range:0~50Hz

·Ambient temperature::-10℃~50℃;

·Relative humidity: ≤95%, Non-condensing

·Working voltage:380VAC