Based on measuring corrosion loss of metal, the high precision electrical resistance probe corrosion monitoring system can calculate corrosion loss rate by measuring changes of AC signals caused by the thickness reduction of corrosion sample. The system features high sensitivity, quick response, strong anti-disturbing capacity and extensive application. It is extensively and successfully applied nationwide at present. By applying the same theory, measuring sample may be made in tubular, flush and various shapes to adapt to various application view angles.

Features

·Indirect corrosion measurement: pipeline corrosion rate caused by medium can be indirectly reflected by element corrosion rate, which is calculated according to the accumulation of thickness reduction by corrosion over a period of time

·Irrelevant to the corrosion system: it can measure liquid phase corrosion and gas phase corrosion, and can be applied to the electrolyte corrosion system and non-electrolyte corrosion system

·It is a comparatively universally used online corrosion monitoring method with strong anti-disturbing capacity by applying AC signals as measuring signals

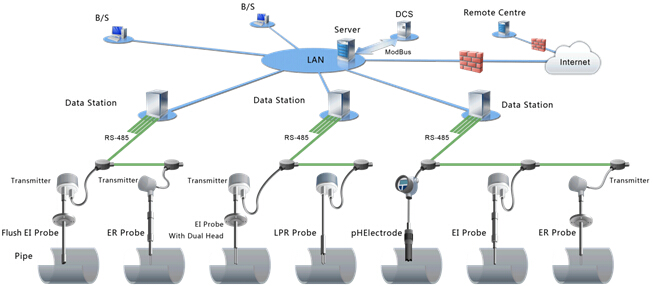

Typical configuration of high precision ER probe system-wire

RS485/4-20mA/ Modbus

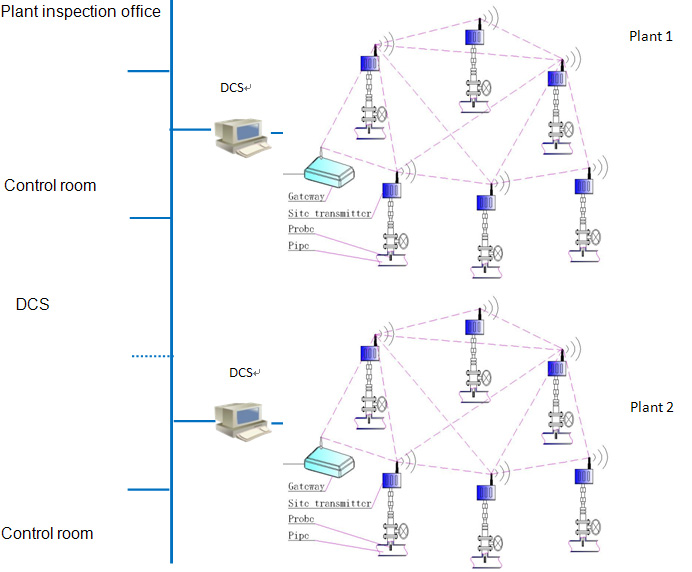

Typical configuration of high precision ER probe system-Data logger

Typical configuration of high precision ER probe system-Wireless

Typical items for the system

1.High precision ER probe

·Fixed (flange) probe

·Retractable probe

·High-pressure probe

2.Transmitter, data logger or transmitter/data logger

3.Data transfer unit

4.Adaptor

5.Access fitting/ Stuffing box

6.Connection cable

7.Junction box

8.Power & interface module

9.Special software/ corrosion management system