Equipment corrosion monitoring technology, including online probe technology and online thickness measurement technology, has made remarkable progress in recent years. As the process monitoring technology, online probe technology with high measuring precision plays an important role in process corrosion monitoring, material evaluation, agent guidance, etc. This also shows deficiency in petrochemical enterprises application. Its indirect measurement method fails to provide residual wall thickness and local corrosion information. Though online ultrasonic thickness measurement technology developed in the past few years could directly measure residual wall thickness of pipelines, each unit of this system can only monitor less than 0.5 cm2, which features low efficiency, high costs and poor practicability. ZKWELL electric field matrix wall thickness monitoring system perfectly solved those problems. The system can directly measure pipeline local corrosion, residual wall thickness without apertures and even over 100cm2 detection area of each unit. This high-efficiency system is an innovative technology, which makes a great breakthrough in online monitoring of uniform corrosion and local corrosion for on-service pipelines and equipments.

Measuring electrode is arranged to monitored equipments or outer wall of pipelines according to a certain matrix. Low frequency inductance signal will be generated on the electrode by monitoring system; meanwhile, the system will collect, enlarge and process in real time those response signals sent by different matrixes at different times. Finally provide corrosion information through operational model and make 3D corrosion wall loss drawing.

Technical Features

·Directly inspect uniform corrosion, pitting corrosion and erosion of on-service equipments and pipelines in typical range;

·Direct measurement with no apertures and long life matrix electrode, features with high reliability and low maintenance cost;

·Wired and wireless transmission mode, which can directly incorporate into the enterprise’s current online corrosion monitoring system;

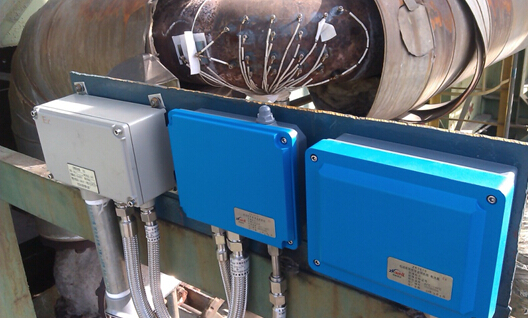

·Probe connection method: clamped or welded to pipelines;

·3D display of pipeline corrosion, pipeline lifetime and operation risk judgement and assessment.

System Structure

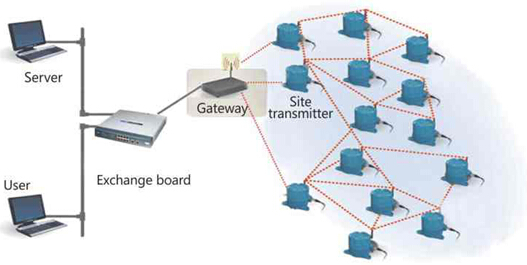

E field matrix wall thickness monitoring system includes two structures: wireless and wired transmission.

·ZK-3600, main devices of wireless transmission structure: E field online pipeline monitor, wireless gateway, wireless relay, data analysis software.

·ZK-3610, main devices of wired transmission structure: online pipeline monitor, safety barrier power and communication converter, transmission cable, remote terminal and data analysis software.

·Measurement thickness range: <20mm

·Sensitivity: 0.1mm

·Wall temperature of equipment and pipeline: <600℃

·Ambient temperature of monitoring instrument: -40℃~80℃

·Data acquisition frequency: 10min ~ 24h (can be set)

·Communication method: wired- RS485

wireless-ZigBee network model and GSM Mobile Network Model, wireless Hart

·Explosion-proof grade: Ex ibII CT4